Effective management of a fresh produce shipping business necessitates the strategic application of efficiency-enhancing tools.

Increasing demands within this sector compel us to rethink and streamline our operations.

While the logistics of shipping fruits and vegetables are undeniably complex, it is not an insurmountable challenge.

With the right tools at one’s disposal, the efficiency of these processes can be dramatically improved.

The purpose of this article is to highlight these instrumental solutions.

These can play a pivotal role in boosting the overall productivity of your produce shipping business operations.

Contents

- Tools For Increasing Efficiency In Produce Shipping Business

- 1. Advanced GPS tracking systems.

- 2. Automated Inventory Management Software

- 3. Efficient Packaging Solutions

- 4. Digital Invoicing and Billing Systems

- 5. Advanced temperature control technology

- 6. Real-time Fleet Management Systems

- 7. Refined Route Optimization Software

- 8. Cross-docking Facilities

- 9. Use of Renewable Energy Vehicles

- 10. Electronic Data Interchange (EDI) system

- The Bottom Line

Tools For Increasing Efficiency In Produce Shipping Business

1. Advanced GPS tracking systems.

Advanced GPS tracking systems are becoming increasingly important in the produce shipping business.

These systems allow for unprecedented tracking and monitoring of transport vehicles, assuring both the company and the consumer of the produce’s precise location at any given time.

This immediate availability of positional data can greatly increase efficiency by enabling proactive adjustments to any unexpected delays or barriers.

With real-time access to delivery updates, any necessary diversion can be swiftly communicated to the driver, thereby minimizing downtime.

Furthermore, using GPS tracking systems allows for more reliable scheduling and dispatching of shipments.

By analyzing previous delivery routes and times, potential inefficiencies can be identified and avoided.

Improved route planning not only reduces fuel consumption and vehicle wear, but it also allows for more shipments to be completed within the same timeframe.

Additionally, GPS systems can assist with asset optimization.

Through tracking the exact location, speed, and route of each vehicle, fleets can be managed more effectively – potentially reducing the need for additional vehicles or drivers.

Moreover, tracing the condition and quality of produce during transport is made possible through GPS technologies.

By linking GPS data with temperature and humidity sensors, possible disruptions or deteriorations in produce quality can be identified and addressed in real time.

Advanced GPS systems offer an unprecedented level of control, visibility, and efficiency – paving the way for more efficient operations and improved customer satisfaction.

In essence, GPS tracking systems provide an all-encompassing solution for increasing efficiency in the produce shipping business.

They not only reduce uncertainties and inefficiencies but also facilitate transparency in the whole shipping process – a feature significantly appreciated by end consumers.

Indeed, the enhanced visibility offered by advanced GPS tracking systems has the potential to transform the logistics industry, making it more streamlined, reliable, and efficient.

In the highly competitive world of produce shipping, staying abreast of the latest, most efficient technologies, like advanced GPS tracking systems, is key to maintaining a competitive edge.

2. Automated Inventory Management Software

One tool that can significantly contribute to increasing efficiency in the produce shipping business is the use of Automated Inventory Management Software.

This technology allows businesses to track their inventory in real-time, reducing the risk of overstocking or understocking items, leading to improved efficiency.

With this software, companies can have a complete overview of their inventory, allowing them to make more informed decisions.

It can also significantly reduce the time and effort required to manage inventory manually.

Automated Inventory Management Software uses algorithms and data analysis tools to predict demand patterns and trends.

Automated inventory management software is a key tool to not only track inventory but also assist in predicting and managing demand.

Companies can leverage this information to ensure they always have the appropriate amount of stock available, boosting their operational efficiency.

Moreover, it can also minimize wastage by ensuring that perishable items like produce are sold before they spoil, further enhancing the profitability and efficiency.

The use of this software can also lead to increased accuracy in inventory reporting, reducing the chances of errors that can lead to delays or losses.

Moreover, automated inventory management software can often be integrated with other systems, such as billing or shipping software, further increasing its utility.

Through these integrations, companies can have a holistic view of their operations and make more strategic decisions.

This software can also provide valuable data that can be used to gain insights into the company’s performance, allowing them to identify areas that need improvement and implement accordingly.

Automation of inventory management can therefore significantly contribute to the overall efficiency of the produce shipping business.

Moreover, as the software keeps evolving, companies can constantly update their processes, leading to continuous improvement in efficiency.

Therefore, investing in a robust and efficient automated inventory management software can be a significant step towards increasing efficiency in the produce shipping business.

With this tool, businesses can manage their inventory more effectively and efficiently, leading to improved profitability and customer satisfaction.

3. Efficient Packaging Solutions

The effectiveness of produce shipping depends significantly on the proper use of efficient packaging solutions.

Effective packaging plays an instrumental role in protecting the condition and quality of products during transit.

A variety of materials are employed, including cushioned packaging, thermal insulation, and sturdy boxes, all geared towards preserving the freshness and nutritional content of the produce.

Utilizing customized packaging solutions not only safeguards products but also enhances storage efficiency significantly, ensuring that the available space is maximally utilized.

In addition to saving space, well-structured packaging can also contribute to cutting down fuel usage and emissions through reducing the overall weight and size of the shipment.

Well-designed packaging solutions can aid in optimizing load planning, which is another critical component of shipping and logistics.

This means that more produce can be shipped in the same space, resulting in increased efficiency and profitability.

The use of packaging technology also helps in tracking the shipment, with barcodes or smart labels embedded on the packaging to monitor and track the consignment during transit.

This makes it easy to locate shipments and reduce the chances of any misplacement, thereby improving the overall operational efficiency of the business.

Next-generation packaging solutions are also promoting sustainability in the produce shipping business.

For instance, companies are increasingly turning to bio-based and recyclable materials for their packaging solutions, significantly reducing their carbon footprint.

Advanced packaging technologies have introduced active and intelligent packaging, which extends the shelf life of produce and maintains its quality by regulating humidity, absorbing ethylene and monitoring temperature.

This not only keeps the produce fresh for longer periods but also reduces wastage and losses due to spoiled or damaged goods, enabling businesses to serve their customers better.

Therefore, smart and efficient packaging solutions are a powerful tool for increasing efficiency in the produce shipping business.

They not only enhance product protection and space utilization but also ensure effective shipment tracking, promote sustainability, and facilitate improved customer service.

4. Digital Invoicing and Billing Systems

In the produce shipping business, the use of digital invoicing and billing systems represents an important tool that increases efficiency.

Transactions are regular and numerous, and traditional methods of invoicing and billing prove to be both tedious and prone to error.

On the other hand, digital invoicing and billing systems automate these processes, greatly improving efficiency and reducing the instances of human error.

These systems operate in virtual environments and thus facilitate quick and seamless online transactions.

The use of digital invoicing and billing systems ensures accuracy, and this helps to build trust and maintain good relationships with customers.

An additional advantage is that they are easy to use and navigate, which simplifies the work for employees.

Advanced digital invoicing systems also come with additional features, such as the ability to track and manage multiple invoices simultaneously, which further increases efficiency.

With these systems, one can easily track payment status, helping companies stay on top of their finances.

Another key benefit of digital invoicing and billing systems is that they require lesser physical storage space, which eliminates the need for maintaining huge paper files.

Moreover, these systems promote sustainability by reducing paper use.

Digital invoicing and billing systems also come with built-in security measures that protect financial data from external threats.

It is even possible to integrate these systems with other software used in the business for holistic management.

Advanced analytics provided by these systems also help businesses to gain insights into their financial performance and strategize for the future.

Considering the numerous benefits offered, it becomes evident that digital invoicing and billing systems are crucial tools for increasing efficiency in the produce shipping business.

Finally, businesses should choose digital invoicing and billing systems that best meet their unique needs to maximize the benefits.

5. Advanced temperature control technology

When dealing with produce shipping business, one cannot emphasize enough the critical role that temperature control plays in product quality.

The essence of advanced temperature control technology remains maintaining the freshness and quality of produce from the point of harvest to the final consumer.

To put things into perspective, subtle changes in temperature can lead to rapid ripening, rot, or freeze of produce thereby causing tangible financial losses for the whole supply chain.

Implementing advanced temperature control technology, however, can help stabilize these temperatures and mitigates such risks.

The temperature control process begins right from the field where produce is harvested and involves sophisticated control systems during transportation and storage.

Modern temperature control systems are complete with sensors, cooling units, and refrigerated cargo spaces.

These systems not only maintain the desired temperatures, but they also accurately monitor and record temperature and humidity levels in real-time.

This real-time feedback allows for swift adjustments thereby preserving the quality and freshness of the produce.

Furthermore, advancements in phone applications and Internet of Things (IoT) technologies can provide immediate temperature data access for continuous monitoring.

Even more remarkably, some advanced temperature control technologies now incorporate predictive functionalities.

These functionalities leverage mathematical models to predict temperature trends and fluctuations based on the current and historical data, allowing managers to take proactive measures to prevent any potential product damage.

Without a doubt, this contributes significantly towards reducing product waste and increasing the efficiency of the produce shipping business.

While investing in advanced temperature control technology might incur its upfront costs, the long term pay-offs in terms of improved product quality, customer satisfaction and reputation makes it a profitable investment.

Moreover, advanced temperature control technology not only supports business efficiency, but also promotes sustainable practices by minimizing food waste.

To sum it up, advanced temperature control technology remains a crucial tool that can drastically transform and streamline the operational processes involved in produce shipping business.

6. Real-time Fleet Management Systems

Key to spurring efficiency in the produce shipping business, real-time fleet management systems offer an array of benefits through their use of advanced technology.

These systems are designed to give businesses complete control over their fleet, enabling real-time tracking of vehicles and on-the-spot decision making.

Making use of software applications and GPS technology, these systems can provide real-time information about a vehicle’s location, speed, idle time, route, and deliveries.

This information is not only crucial for managing day-to-day operations but also for making longer-term strategic decisions about fleet management and efficiency.

Through the data garnered from these systems, businesses can gain critical insights that can facilitate measures for fuel efficiency, economical route management, and preventive fleet maintenance.

Further, real-time fleet management systems can significantly enhance the communication between a business and its drivers leading to greater operational efficiency.

This enhancement is typically carried out through a live map, email, or text notifications updating fleets about traffic jams, route changes, delays, or early real-time deliverances.

The direct result of this real-time communication is a reduction in delivery timeframes, ensuring that the freshness and quality of the produce is optimally preserved.

Additionally, these systems can facilitate significant cost savings by highlighting fuel inefficient vehicles, prompting timely vehicle maintenance, or suggesting more efficient dispatch methods.

Real-time fleet management systems are also instrumental in ensuring driver safety and compliance with transport and safety regulations.

For instance, the systems can alert managers to potential driver fatigue, allowing for preventive measures to be taken and therefore ensuring not only driver safety but also the protection of the produce cargo.

Businesses that adopt these systems can also benefit from improved customer satisfaction due to enhanced predictability of delivery timeframes.

Given that produce is a perishable product, ensuring timely deliveries and the ability to provide customers with real-time updates is crucial for maintaining business reputation and customer loyalty.

Moreover, the wealth of data generated by these systems can be leveraged to streamline operations, and provide important analytics that enable strategic business growth.

While the initial investment in these systems can be substantial, the return in terms of efficiency, safety, customer satisfaction, and overall cost savings makes it a vital tool for businesses seeking to increase efficiency in the produce shipping industry.

7. Refined Route Optimization Software

In the produce shipping business, route optimization is more than just finding the shortest path between two points.

It involves considering multiple variables such as traffic conditions, weather patterns, and the delivery deadlines of different shipments.

This is where refined route optimization software comes into play.

These sophisticated systems use algorithms to automate the process of determining the most efficient routes.

This not only saves time but also minimizes fuel consumption and reduces the overall cost of operations.

By adopting refined route optimization software, businesses can significantly increase their operational efficiency while minimizing environmental impact.

For instance, the software can adjust routes in real-time based on current traffic conditions to ensure that deliveries are made on time.

Furthermore, the system can predict and plan for future conditions such as predicted traffic patterns, road closures, or weather conditions.

This forms an essential part of proactive planning in a produce shipping business.

Also, these softwares often come with easy-to-use interfaces which aid in the manual adjustment of routes when necessary.

Therefore, it allows for greater flexibility in operations.

Moreover, by using route optimization software, the shipping business can easily monitor the progress of their fleets in real-time.

This helps in identifying bottlenecks in the routes and take quick decisions to optimize operations.

The route optimization not only impacts the efficiency of deliveries but also plays an essential role in customer satisfaction.

By ensuring on-time deliveries, the business can build strong relationships with their customers leading to repeat businesses.

Finally, the integration of refined route optimization software with other tools like advanced GPS tracking systems and real-time fleet management systems can lead to a more holistic approach towards increasing efficiency in a produce shipping business.

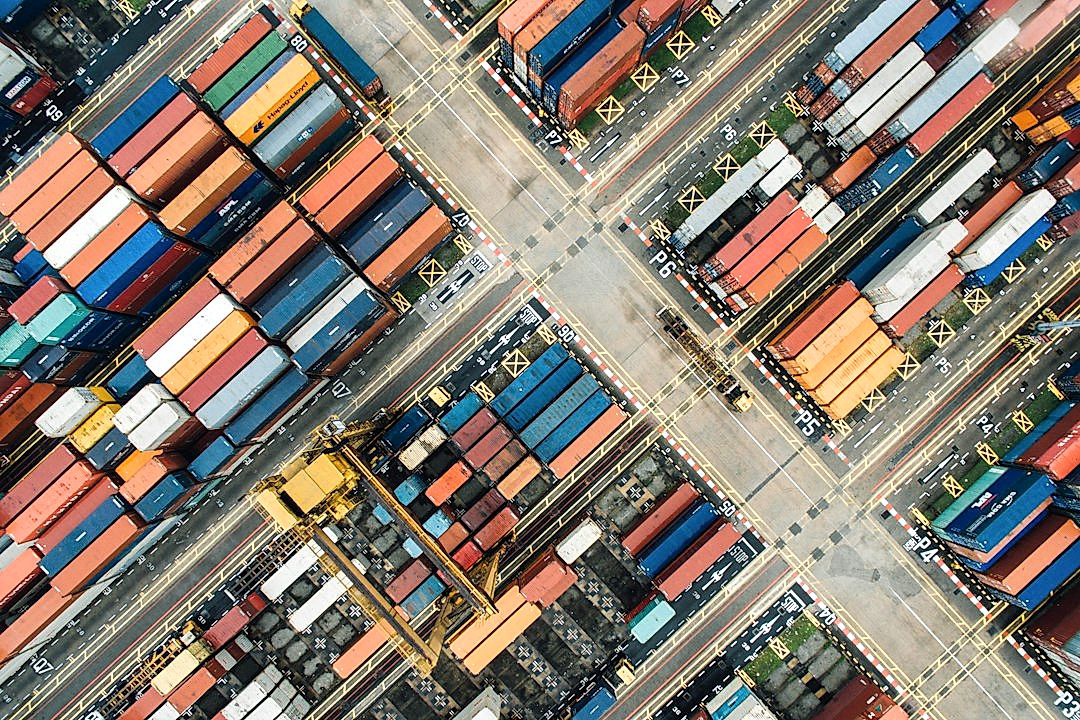

8. Cross-docking Facilities

Cross-docking is an essential logistical strategy used in various industries, including produce shipping business, to reduce storage time and optimize delivery procedures.

The process involves transferring products directly from an inbound transport to an outbound transport, therefore minimizing or completely eradicating the need for storage.

Improved efficiency in the supply chain is one of the significant benefits of implementing cross-docking facilities.

Less time spent storing products reduces overhead costs and makes the operation leaner and more competitive.

This practice allows for quick order fulfillment, which increases customer satisfaction and improves the company’s bottom line.

In the context of a produce shipping business, cross-docking is particularly beneficial due to the perishable nature of the products involved.

Products like fruits and vegetables have a short lifespan; therefore, reducing the time spent in storage helps maintain the freshness and quality of the produce.

Cross-docking facilities are often structured with several shipping and receiving docks, along with a vast staging area.

The staging area allows for the preparation and sorting of products for the appropriate destinations. This organization helps to streamline the shipping process.

However, deploying a cross-docking system requires strategic planning and investment, including building or renting an ideal facility.

It also requires an advanced tracking system to keep track of incoming and outgoing shipments and ensure everything goes to the right place.

Given the potential benefits, the investment and planning involved in cross-docking could considerably increase efficiency and give a produce shipping business a competitive edge.

Despite the obvious advantages, businesses should evaluate the feasibility of cross-docking, considering their specific operational constraints and needs.

Overall, cross-docking facilities contribute towards operational efficiency, customer satisfaction, and ultimately profitability in a produce shipping business.

It is an exemplary tool that can significantly elevate the standards and efficiency of a produce shipping business.

9. Use of Renewable Energy Vehicles

As part of the forward-thinking measures to increase efficiency in the produce shipping business, the use of renewable energy vehicles is becoming increasingly prevalent.

These vehicles, which can be powered by solar, wind, and other renewable sources, are proving to be a game-changer in the industry.

Not only do they contribute to a reduction in carbon emissions, but their use can result in significant cost savings over time.

In contrast to conventional vehicles that require fossil fuels, renewable energy powered vehicles have the potential to operate at lower costs.

These savings can be attributed to the lower maintenance expenses associated with these types of vehicles and the decreasing costs of renewable energy technologies.

Moreover, the use of renewable energy vehicles in the produce shipping business speaks volumes about the company’s commitment to environmental sustainability.

This sends a positive message to stakeholders, including customers who are more likely to support businesses that actively participate in conserving the environment.

By transitioning to renewable energy-powered vehicles, companies can also enhance their competitiveness in the market.

In a marketplace increasingly focused on sustainability, companies that embrace these technologies can differentiate themselves and gain a distinct competitive edge.

This can also result in a higher degree of customer loyalty and can create opportunities to tap into new markets.

There’s also a potential for these companies to witness an improvement in their company image and reputation.

That being said, transitioning to renewable energy vehicles is not without its challenges.

High upfront costs, infrastructure needs, and technology constraints are some of the potential barriers, but with careful planning and implementation, these can be effectively managed.

Demonstrating a forward-thinking approach, many companies in the produce shipping business are already making strides towards adopting renewable energy vehicles.

This transition is being encouraged by various incentives and support measures provided by governments and environmental organizations, making it a viable and attractive option.

As renewable energy technologies continue to evolve and advance, the use of renewable energy powered vehicles in the produce shipping business is a trend that is expected to grow in the coming years.

10. Electronic Data Interchange (EDI) system

The Electronic Data Interchange (EDI) system has emerged as a powerful tool in the produce shipping business, offering a range of benefits.

It is essentially a computer-to-computer exchange of business documents in a standardized electronic format.

This eliminates the need for paper documents and makes transactions swift, error-free, and efficient.

EDI systems are pivotal in improving operational efficiency in the produce shipping business.

They aid in seamless data synchronization, preventing the occurrence of discrepancies and errors that are common with manual data handling.

Through the use of an EDI system, businesses can automate their data exchange processes.

This reduces the burden on staff, decreases manual input, and thus increases workforce productivity.

Additionally, EDI systems enable real-time data exchange, meaning businesses can make quicker decisions based on accurate and up-to-date information.

An EDI system can also contribute to financial savings in a produce shipping business.

As a result of automated processing and reduced errors, businesses can realize significant cost savings.

Moreover, being a paperless system, it not only reduces costs associated with paper, printing, and storage, but also contributes to a business’s environmental sustainability goals.

In the realm of produce shipping, implementing an EDI system could enhance traceability and transparency.

What this means is that businesses can more accurately track the movement of their products throughout the supply chain.

This assists in the prevention of food wastage, enhances product freshness, and meets the increasing demand of consumers for more transparent food systems.

Implementing an EDI system might seem daunting, but with the right support and training, businesses can reap significant efficiency and productivity benefits in their produce shipping operations.

Therefore, the Electronic Data Interchange (EDI) system stands as a robust tool promising a multitude of benefits, thereby proving its critical role in enhancing efficiency in the produce shipping business.

The Bottom Line

With the rapid evolution of technology, several advancements are revolutionizing the logistics industry.

Advanced GPS tracking systems and real-time fleet management systems have increased visibility, efficiency, and security in the transportation process.

On the other hand, automated inventory management and refined route optimization software have streamlined operations, elevating business productivity.

The adoption of more efficient packaging solutions and digital invoicing systems further optimizes processes, cuts costs, and enhances customer satisfaction.

The use of advanced temperature control technology ensures the quality and safety of sensitive goods.

Moreover, cross-docking facilities have minimized storage costs, whereas the use of renewable energy vehicles represents the industry’s attempt towards sustainable practices.

Lastly, the Electronic Data Interchange system has expedited information exchange, reducing errors, and improving coordination.

In essence, these advancements are not just enhancing operational efficiency but are also driving sustainability in the industry.